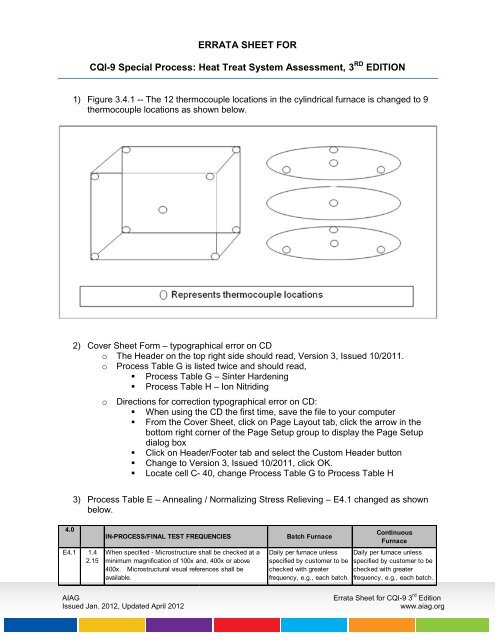

Basic data of the heat treatment organization Audited areas according to the respective CQI-9 process table Contact data auditor, company, participants Results of the CQI audit. Where is calibration mentioned in ISO Don't Miss Another Article! CQI-9 Heat Treatment System Assessment is a self-assessment of the heat treatment system and must be carried out at least once a year. Management responsibility and quality planning Paragraph 2:

| Uploader: | Kirisar |

| Date Added: | 14 September 2008 |

| File Size: | 25.46 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 31273 |

| Price: | Free* [*Free Regsitration Required] |

Method used in calibration. Limitations cq-9 calibration if any. We shall gladly provide you with a contact person and contact data for the above-mentioned project and reference examples upon request. Due date of the next calibration. The management system will emphasize continual improvement, defect prevention and the reduction of variation and waste in the supply chain.

Your contact person Andreas A. What is the difference between Conductivity and TDS? Internal sign-off of calibration results. Calibration requirement for instrumentation is specified in CQI-9 section 3. Technician who performed the calibration.

CQI-9 Heat Treat System Assessment

Never Miss A New Article! Additional questions concerning induction heat treatment.

Where is calibration mentioned in ISO You allways want to be informed about Automotive News? Redaoui Global Sales Manager Phone: As a long standing member of the AIAG, TopQM-Systems already specialized early on in the introduction, development and qualification of employees, as well as auditor training according to the rules of the AIAG for CQI-9 heat treatment processes in the European and global automotive supplier markets. Due date of next calibration.

CQI-9 Special Process Heat Treat System Assessment and Calibration

Management responsibility and quality planning Paragraph 2: Don't Miss Another Article! Name of calibration source- external company name. What is the difference between Calibration and Verification? Process and Test Equipment Requirements A1. Basic data of the heat treatment organization Audited areas according to the respective CQI-9 process table Contact data auditor, company, participants Results of the CQI audit. Make use of our special know-how and contact us for your consultation interview or for an individual, detailed service offer at no charge and without obligation.

Responsibility for material flow and material handling Paragraph 3: It is also implicit in meeting customer requirements the all recording devices such as temperature controllers be calibrated.

Heat treatment facility and equipment Paragraph 3. Technician who performed calibration. CQI-9 Heat Treatment System Assessment is a self-assessment of the heat treatment system and must be carried out at least once a year. The goal is to " include a reduction of campaigns, spills, recalls and warranty claims related to heat treated components. Date the calibration was performed.

Serial number of instrument.

Header and basic data concerning the audited product Questions concerning the process flow Customer-specific requirements concerning the product Operator and quality responsibility Packaging requirements Transport requirements.

Комментариев нет:

Отправить комментарий